Mechanical engineering

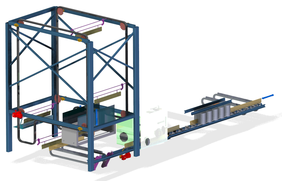

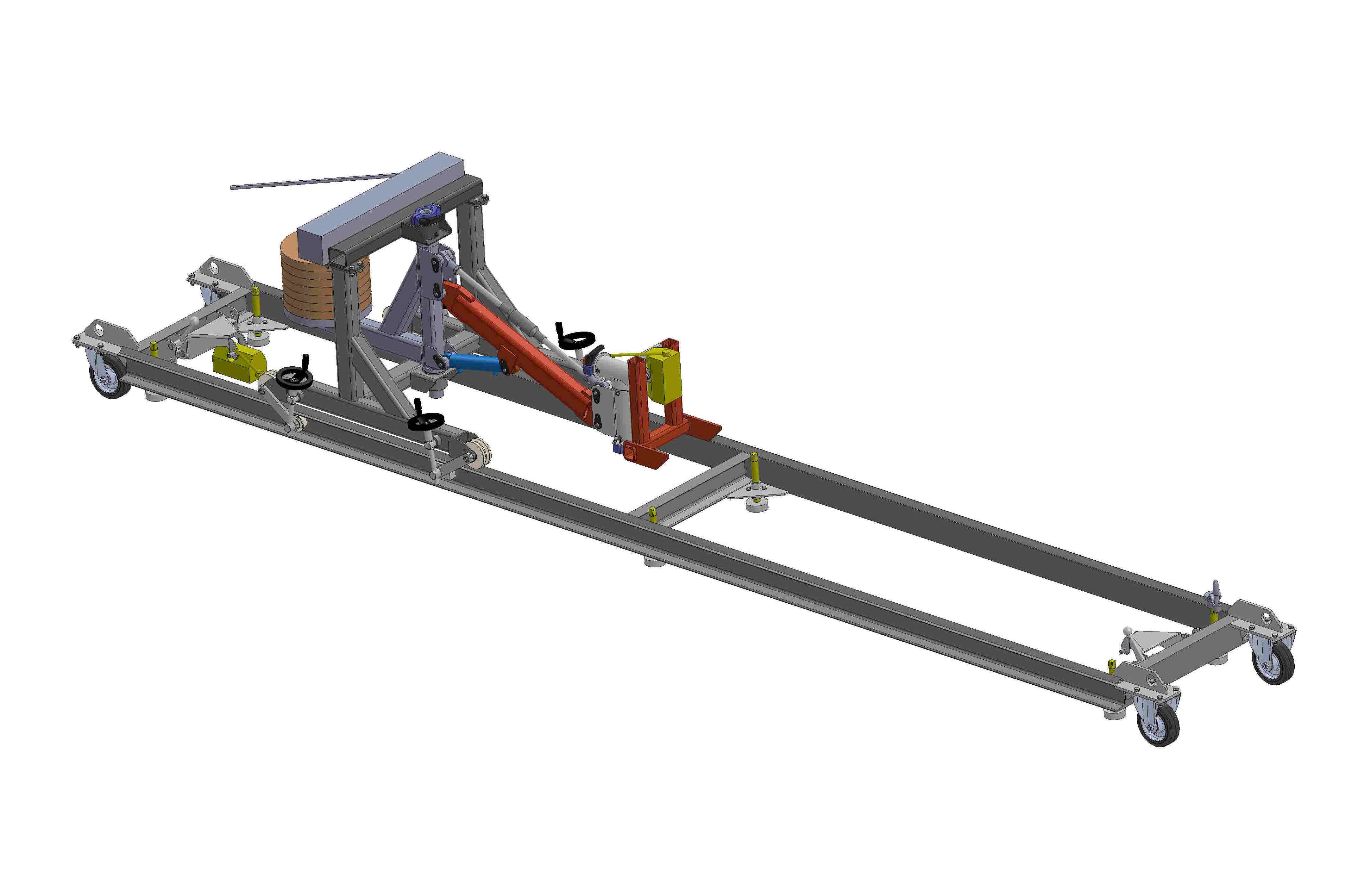

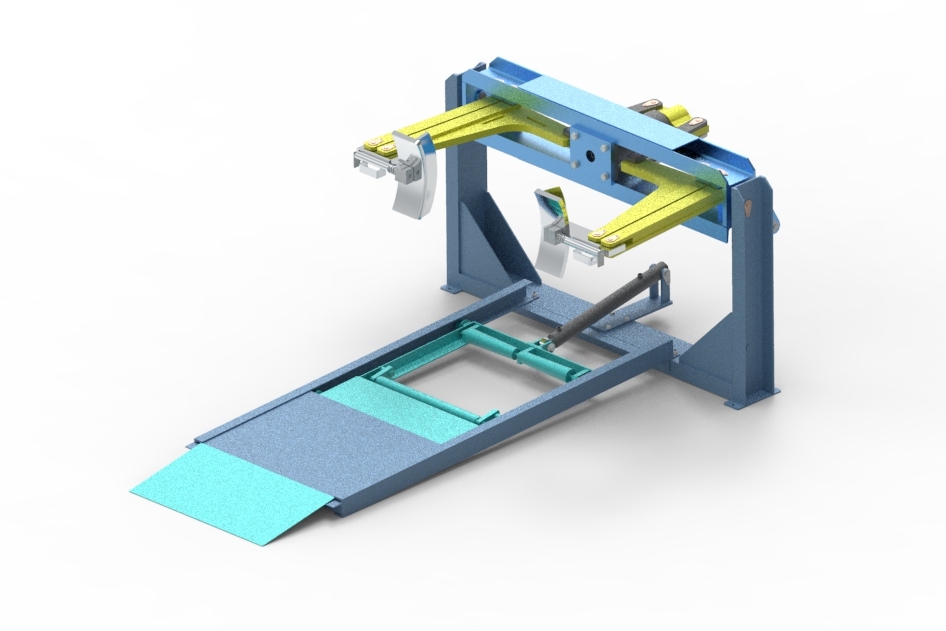

Design of an Automatic woodworking machine

Programmable woodworking machine.

Our clients desire was to perform quickly two machining operations at both ends of a timber board. It was crucial to achieve relatively high productivity and high precision of machining.

The tasks of Nõmm Insenerid OÜ were divided into several stages:

- Sketching involved outlining the general working principles of the machine and making productivity calculations. Results were presented to the customer for approval.

- Main design process involved comprehensive engineering calculations and several stages of risk assessment. It was also our task to create a workflow description as an input for the electrical engineers and PLC programmers.

- Manufacturing and tuning of the machine was mostly task of our good partner. Nõmm Insenerid OÜ was involved at this stage as consultant.

- Finally we had to compile all the user documentation – user and service manuals. As woodworking machines involve many serious hazards this process had to be thorough.

As a result we can proudly declare that the machine has performed almost flawlessly for several years.

Design of machinery for paper and woodworking industry

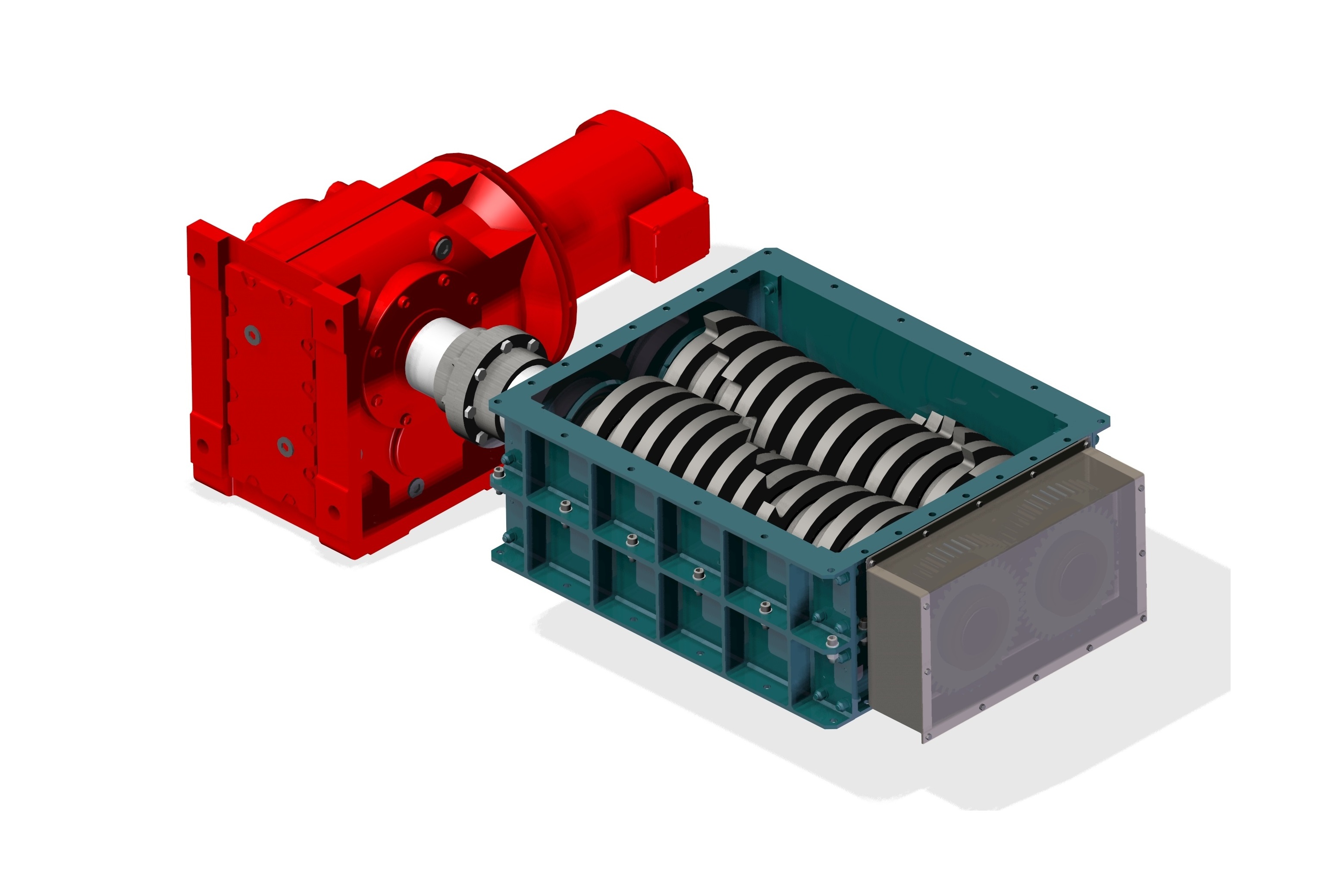

Machinery for metalworking industry

Many machine developments are based on serious engineering calculations. Some examples are:

- Linear plain bearings for horizontal hydraulic press;

- Calculation of gears and selection of couplings for a synchronized rolling machine;

- Machine including crank shafts for operating the tool. Design is based on dynamic force analysis.

Examples of designed production equipment

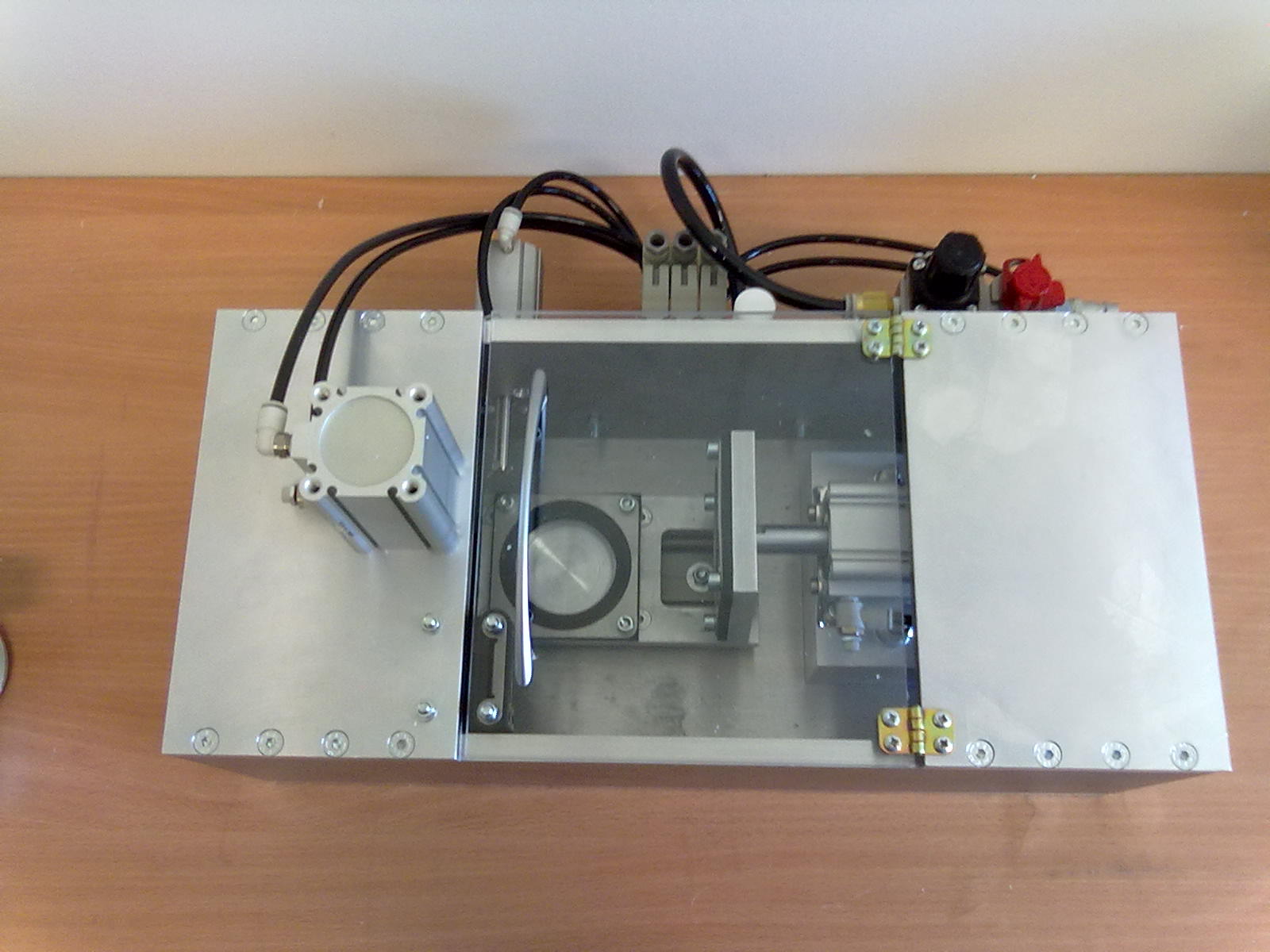

- Design of test rig for hydraulic jack

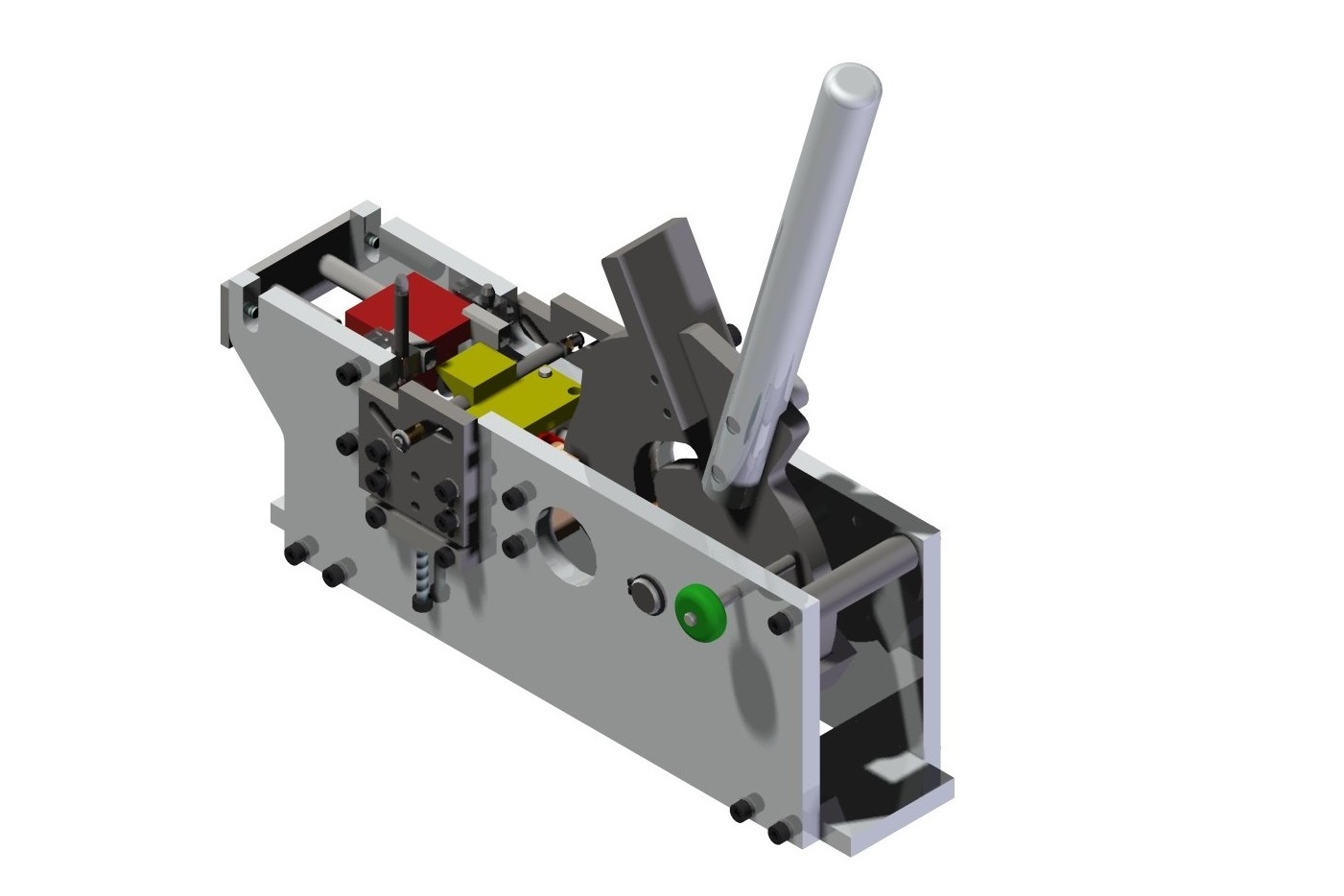

- Design and manufacturing of a bending tool for electronics industry

- Development of riveting tool for electronics industry

- CNC portal milling machine design

- Development and manufacturing of a electronic component test rig

- Design of fine mechanics for optical test rig.

- Design of pallet crusher;

- Pressure testing rig for aluminium die cast products.

- Design of milling fixture for CNC milling machine

- Design of a pendulum saw

- Design of a feeder for woodworking machine

- Design of a perforating machine.

- Engineering of drive mechanism for ground drill

Engineering of a slot milling machine

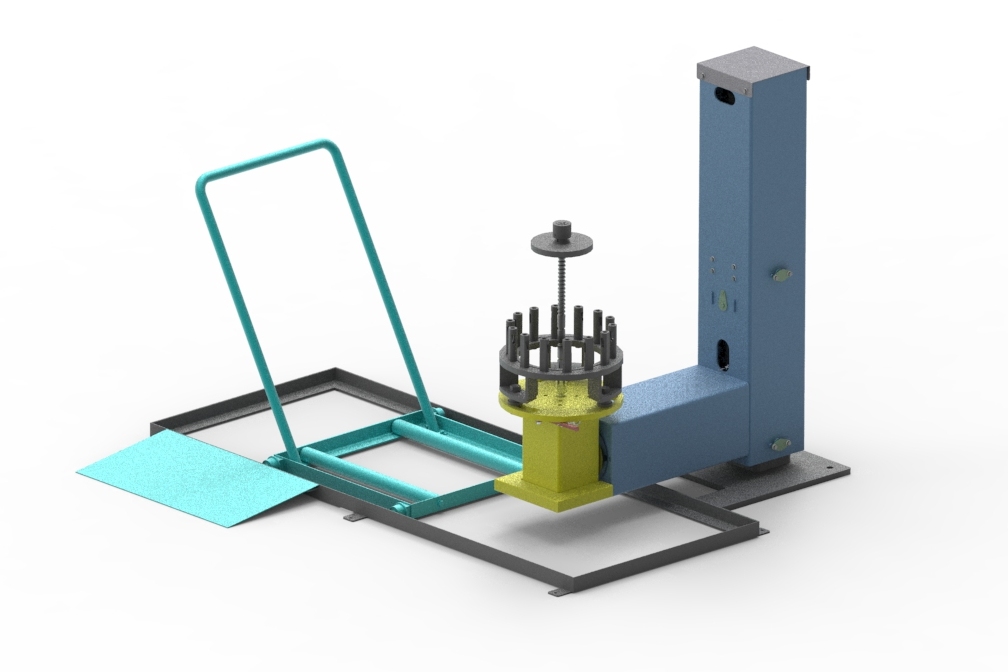

Fixtures and testing equipment

Desing of fixtures and testing equipment

Design of production lines

Nõmm Insenerid OÜ has designed several production lines:

- Curing and washing line for chemical plant;

- Production line for steel painting;

- Machinery and layout for limestone crushing and sorting factory;

- Equipment for transporting and storage of round timber in a plywood factory. Project was interesting due to need of fitting one conveyor into very restricted space.

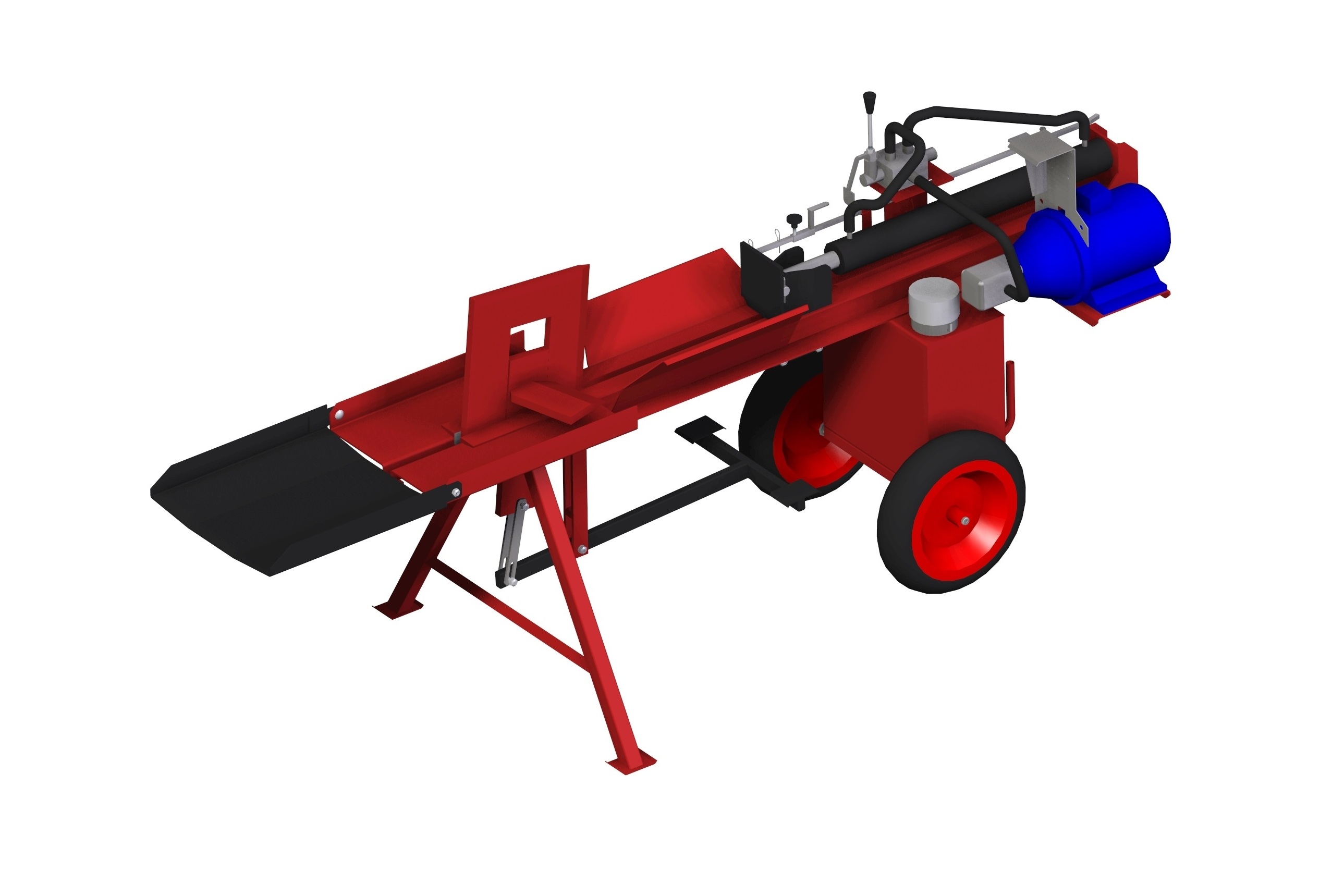

Agrucultural and forestry equipment

Design and development of agricultural machinery

Designs involving ergonomics

Special lifting devices

Design and manufacturing of washing equipment

Specialized washing machines designed by Nõmm

Insenerid OÜ:

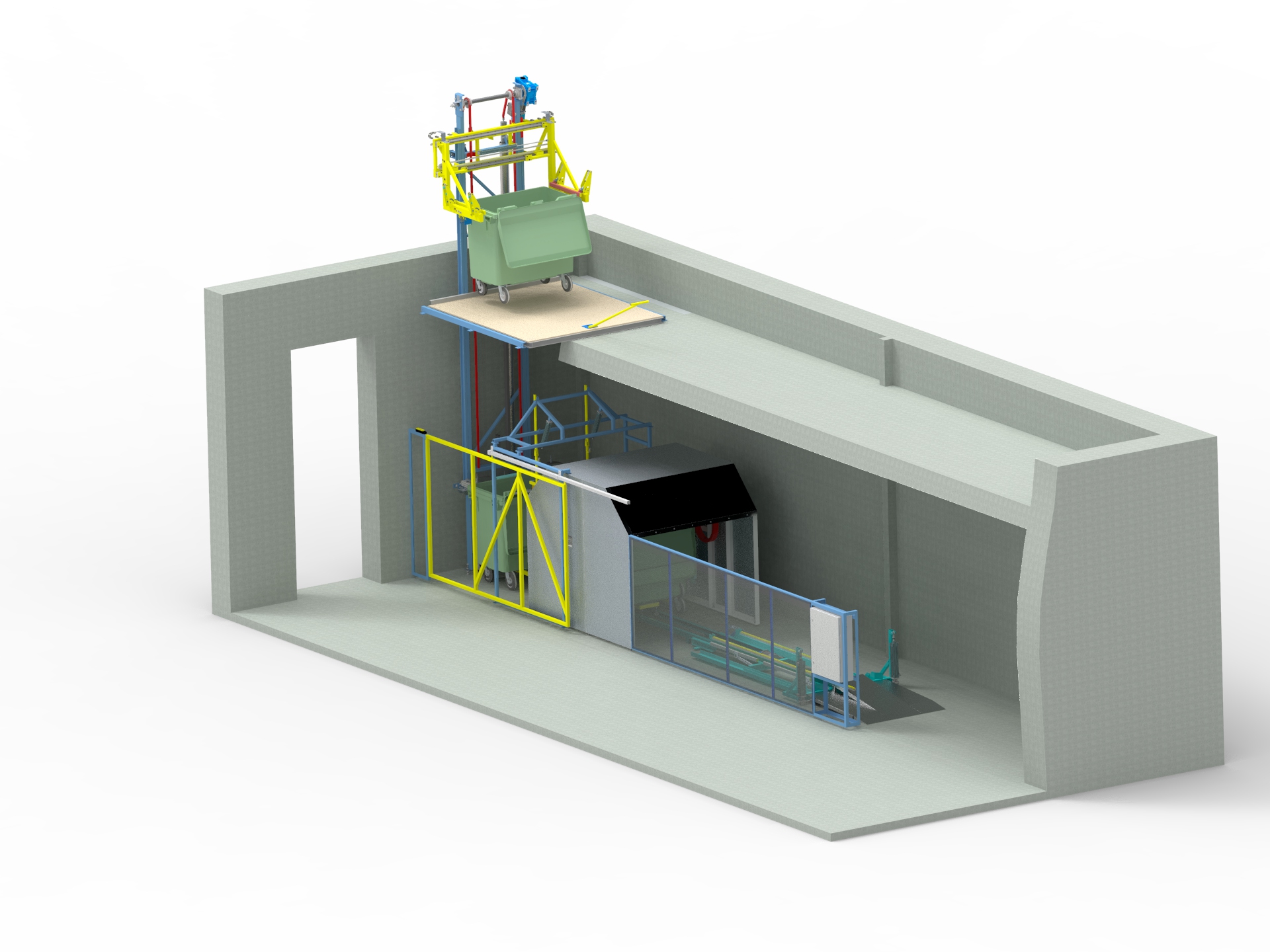

1. Washing line was developed a solution for washing and stacking wheeled

containers.

This machine is able to grab the wheelie bin form a feeding

conveyor and wash it according to the program chosen by operator. A special low-pressure washing head was developed

for this application.

Next to the

washing station is stacking machine. It

is capable of placing containers with

wheels into each other. How many containers is in one stack can be determined

according to the needs of production. Both developed machines are capable of

handling two and four wheel bins.

This

solution is well suited for recycling and waste management companies.

2. Automatic pressure washing machine for wide conveyor belt.

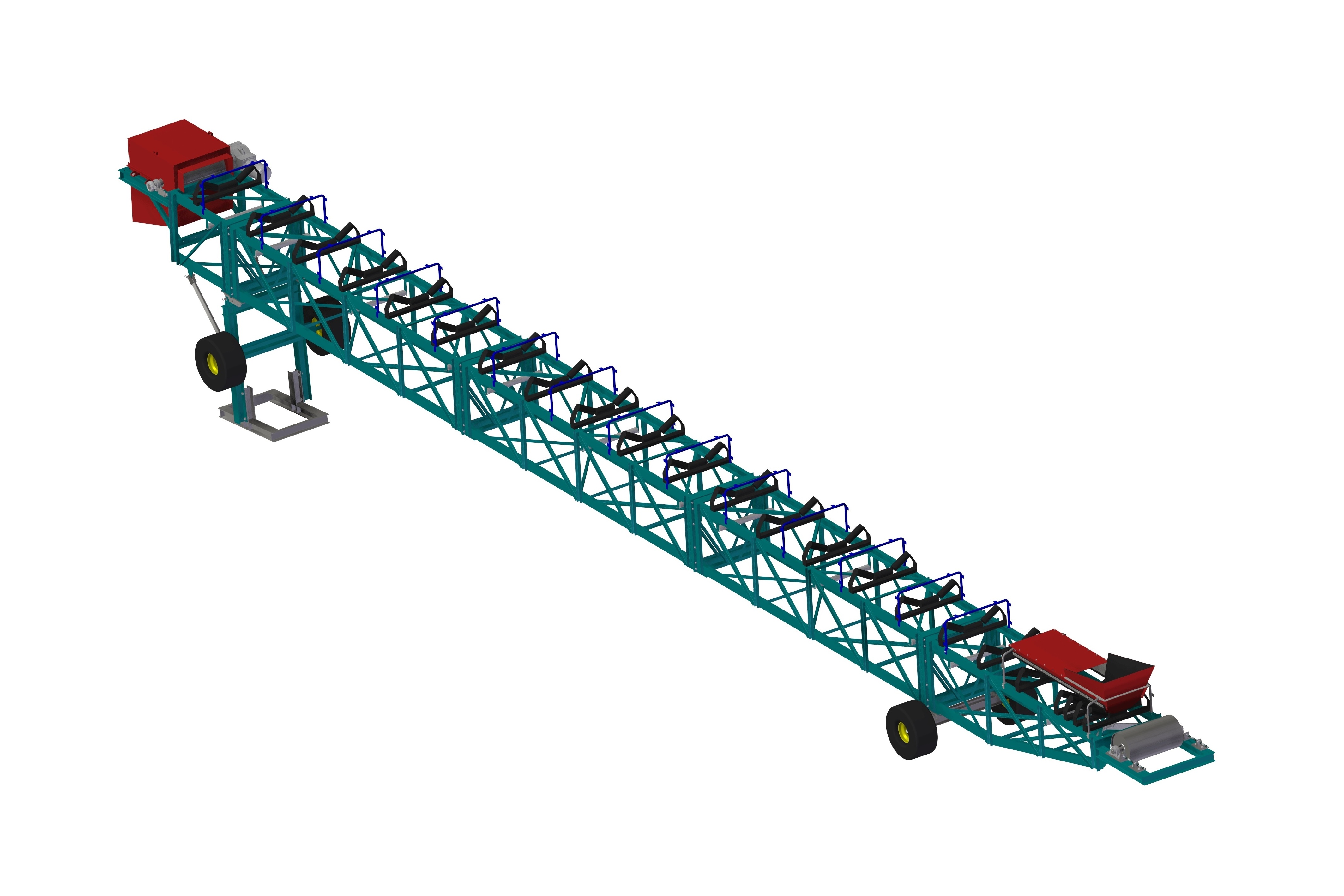

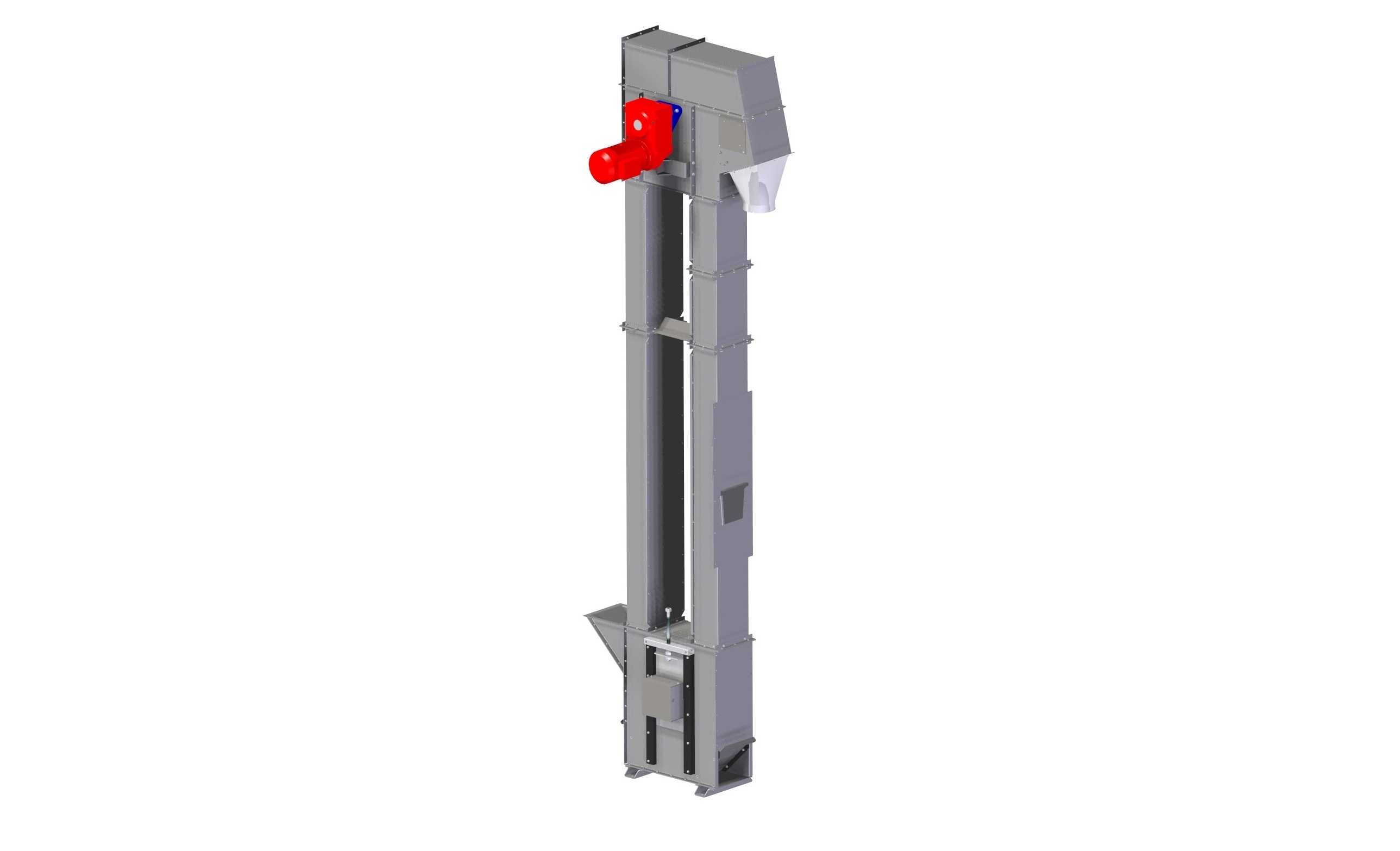

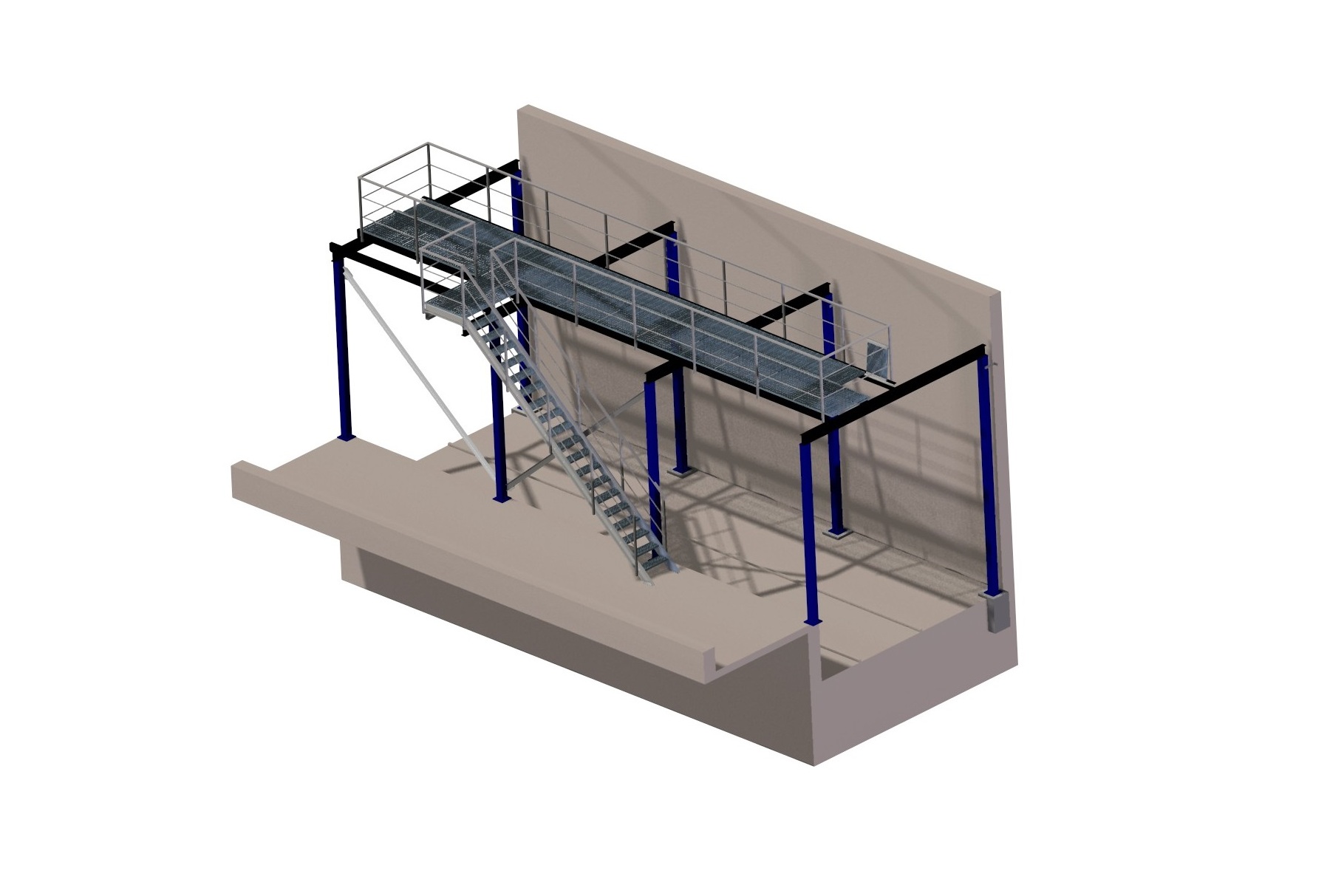

Belt conveyors and bucket elevators

Design of conveyors and transportation equipment

- Layout of conveyors and calculation of steel structures

- Design of a ramp

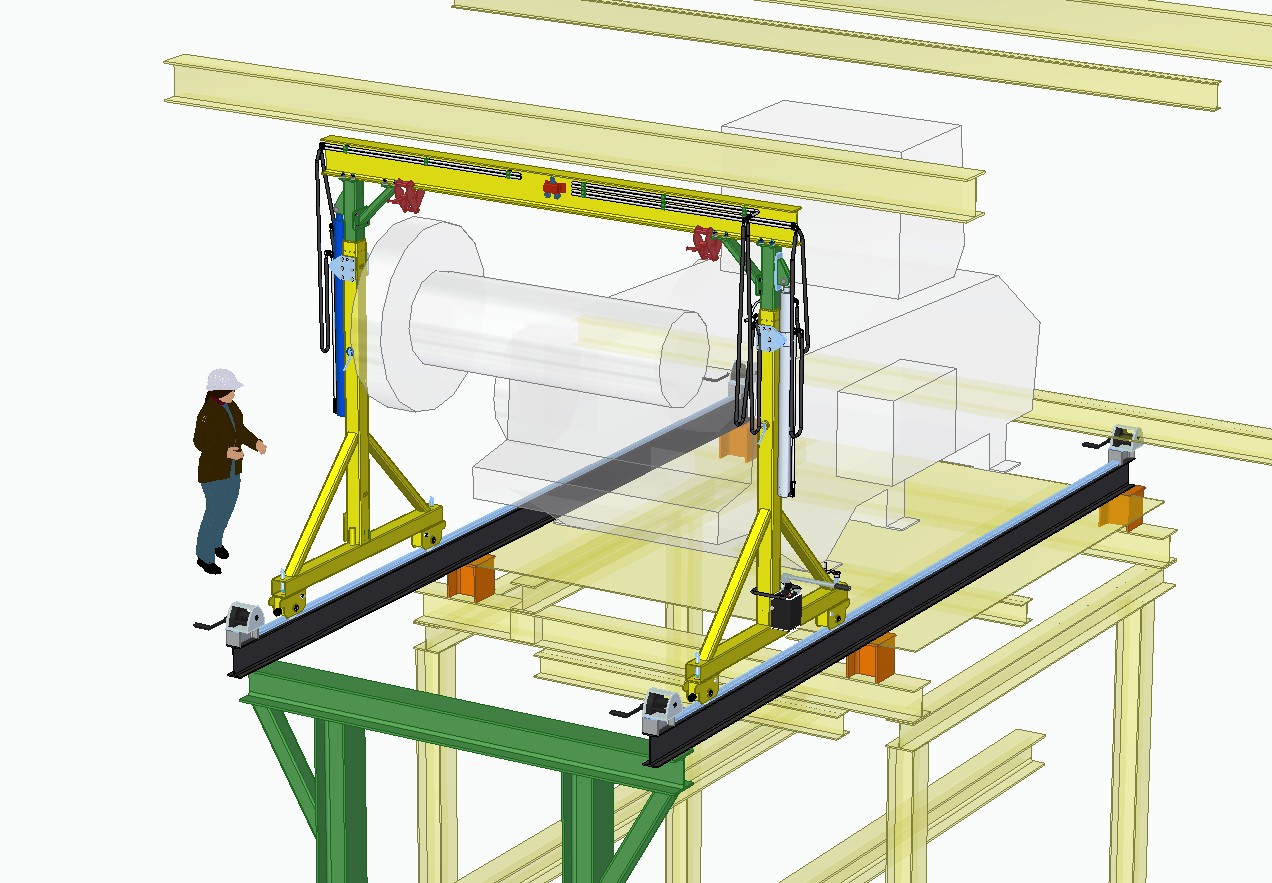

- Design of a panel lifting crane

- Design of a chain conveyor for board stack.

- Design of an extension for sawmill conveyor

- Gravel sorting factory layout, frames and work platforms.

- Adjustable lifting beam design

- Engineering of cross conveyor

- Packaging tape carrier drawings

Silos and hoppers

We have designed several hoppers and silos.

Our projects are based at calculation and design principles described in EVS-EN-ISO standards.

Examples of silos:

- On-site assembled silos for food industry;

- Hopper for agricultural grain storage with a belt conveyor;

- Bolted design silos;

- Welded design silo.

Examples of product development projects

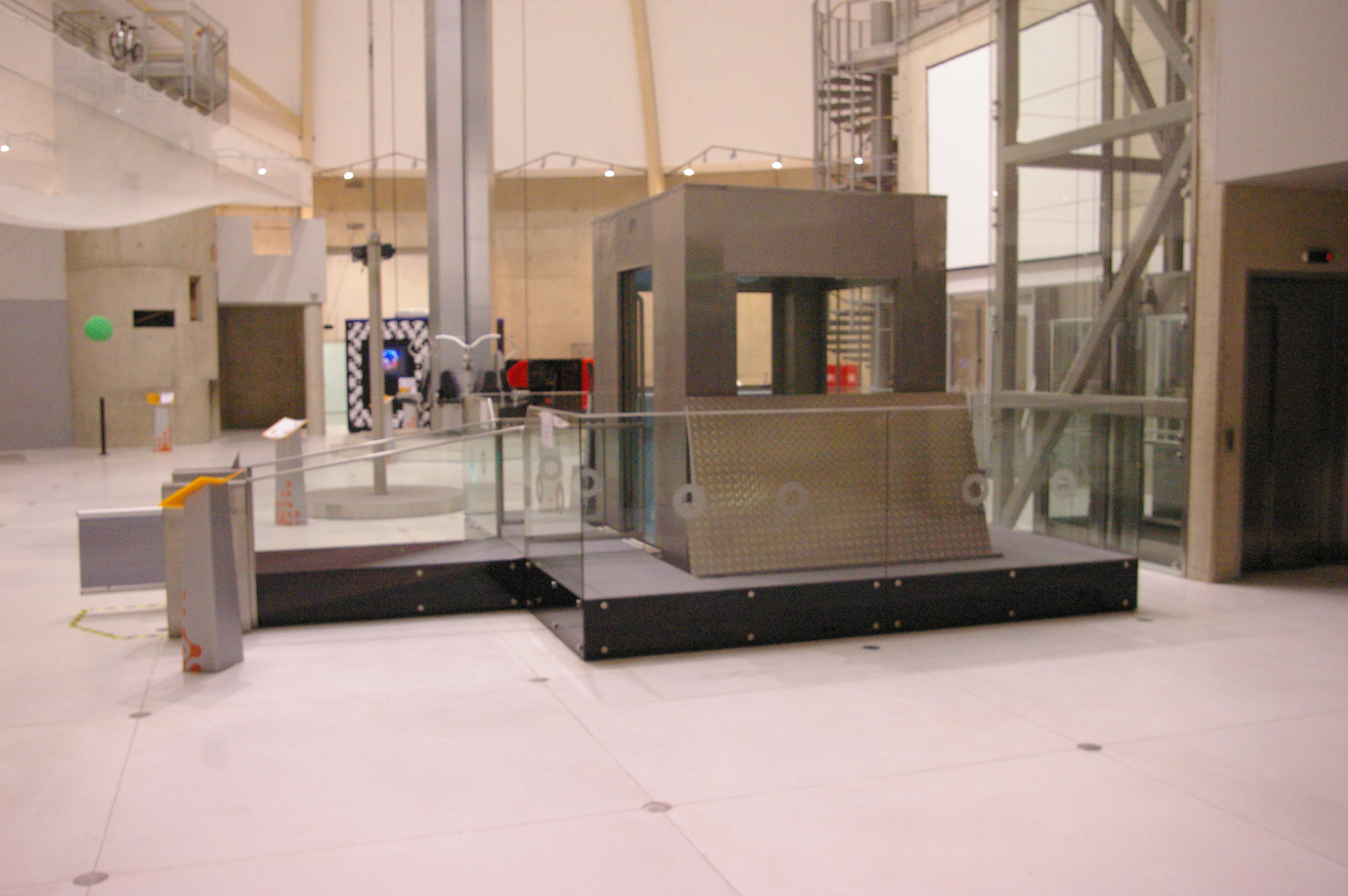

- Design of an attraction “Lift to Australia” to AHHAA centre.

- Design and development of outdoor grills

- Development of automatic cabinet door

- Design of seats for planetarium

- Design of roof hatch with an electric drive

- Expert opinion and risk assessment of peat manufacturing machinery.

- Development of hempseed crushing and sorting process.

- Design of electric scooter frame.

- Design and development of a family of agricultural tractor trailers.

- Development of motorcycle stand

- Design of a vapour generator.

- Design of a planetary transmission.

- Engineering of a fume hood.

- Engineering of sensor housing.

- Development of portable pipe winch.

- Design and manufacturing of a hydraulic module press.

- Design of a bed frame machine

- Drive for rammer

- Development of grain sorter

Machine frames and working platforms

Lifting devices and conveyors

Design of steel structures

- Design and calculation of grain hopper

- Design of a gravel sorting hopper

- Design of a 2,5 MW water heating boiler.

- Design of pontoons for a floating digger

- Engineering of a mould cleaning table

- Drawings for a pallet trolley